- Home

- WATER SOFTENERS

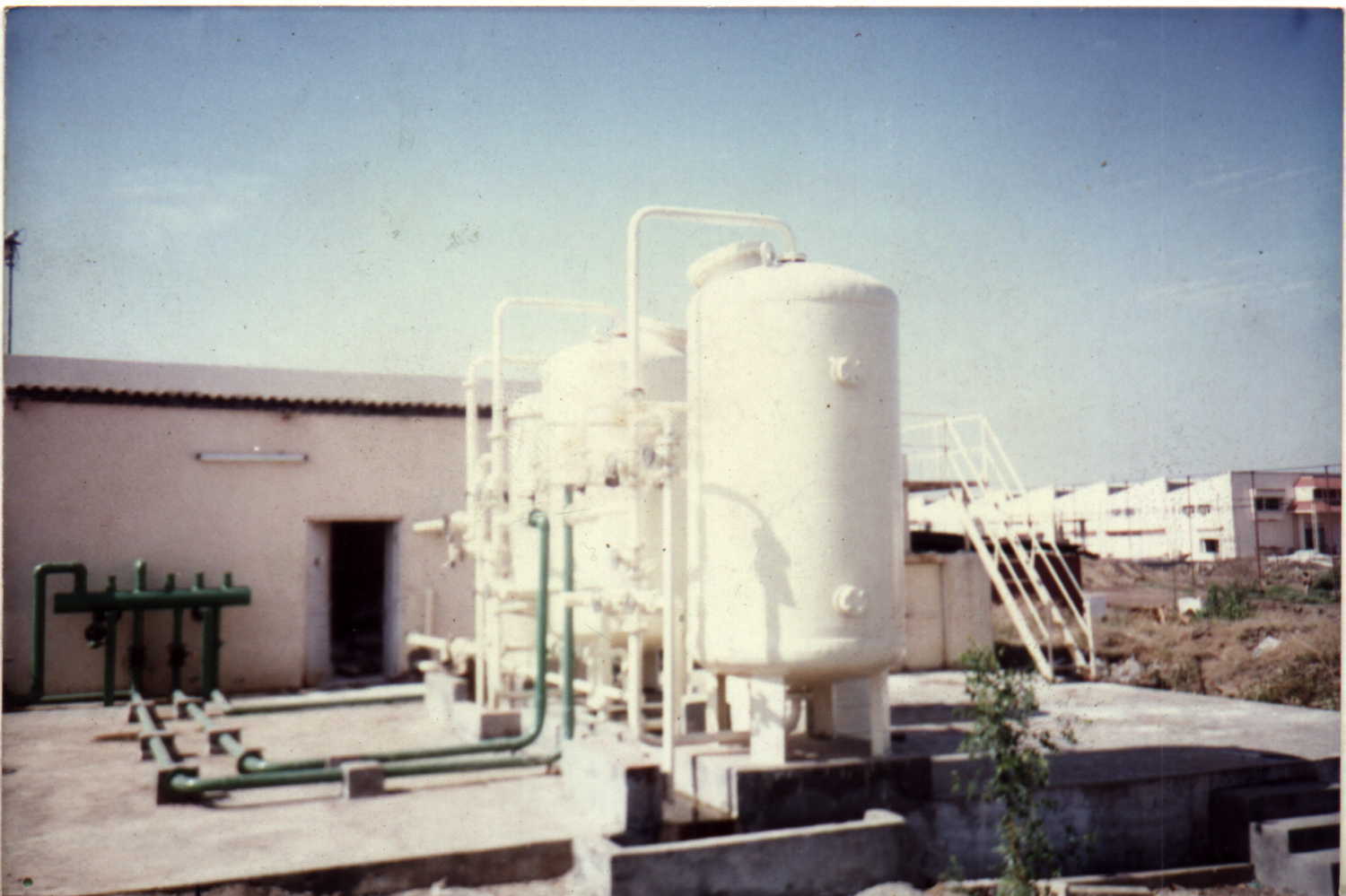

WATER SOFTENERS

INTRODUCTION

With the use of water softening system, the scaling problem either controlled completely or form a very thin soft layer which can easily be removed by high pressure washing or with a very diluted descaling solutions. The use of softener also increase the efficiency of main plant by reducing fuel or power consumptions. The water softening plant work on Ion Exchange technology where strong acid cation exchange resin is used as softening media. This resin release sodium salts which being soluble does not affect the pipeline or vessel through as no scaling is formed due to soft water. This resin require recharging when exhausted due to absorbency of excess Ions of Calcium & Magnesium. The charging chemical used in softener is Sodium Chloride which is very cheap and easily available. The Water Softener consist of M.S. pressure vessel provided with bed plates on to which strainers are fitted either on both side or at the bottom depending of system like up-flow or down-flow working of unit. Cation exchange resin is filled directly on strainer plate.

UNDER DRAIN SYSTEM

Our Water Softeners are consists of a steel pressure vessel or Composite Plastic . Internally they are fitted with a water collecting system and a distribution system for brine and raw water. The Ion Exchange Resin Bed is supported on a steel bed plate on to which screwed polypropylene strainers are tighten to prevent loss of resin and to ensure even collection of treated water.

FRONTAL PIPE WORK & VALVES

All softeners are provided with interconnecting face piping in M.S. comprising of inlet, outlet and back wash lines complete with valves and regeneration arrangement for auto injection of brine solution from brine preparation tank through power ejector & valve. The waste effluents are directed to a drain sump for which a pipe to drain should be connected.

ION EXCHANGE RESIN

ACCESSORIES

- PE / FRP / M.S. Rubber lined Brine Preparation Tank.

- I. / M.S. Rubber Lined Ejector with PVC Suction line.

- Air release valve with connecting piping.

- 100 mm dia. bourdon type steel pressure gauges with stainless steel isolation valve and connecting piping on inlet.

- Sampling cocks on soft water outlet line.

- Hardness Test Kit

Available in different sizes and capacity ranges from 5 cum. to 100 cum. per hour rate of flow. For best designing of suitable softener, kindly provide complete detail as per below on our E-Mail : vkenvirotech@gmail.com :

- Flow rate through water softener.

- Output capacity between regeneration (OBR)

- Source of water and feed water analysis ( routine water test )

- Application of soft water

TECHNICAL DATA OF WATER SOFTENERS | ||||||||||

Sr. Nos. | Model | Diameter (mm) | H.O.S.(mm) | Thickness (mm) | Frontal Piping (mm) | Max. Flow Rate m3/hr. | Resin Qty. in (Liters) | Resin Tank Diameter Depth (mm) | Remarks | |

Shell | Dish End | |||||||||

1.a | ENVIROX –600 SU | 600 | 1500 | 5 | 6 | 50 | 11 | 400 | 600 x 900 | MSEP |

1.b | ENVIROX –600 SD | 600 | 2000 | 5 | 6 | 40/50 | 7.5 / 11 | 210-350 | 600 x 900 | MSEP |

1.c | ENVIROX –600 SDB | 600 | 2500 | 5 | 6 | 40 / 50 | 7.5 / 11 | 350-500 | 800 x 900 | MSEP |

2.a | ENVIROX – 800 SU | 800 | 1500 | 5 | 6 | 50 | 20 | 750 | 800 x 900 | MSEP |

2.b | ENVIROX – 800 SD | 800 | 2000 | 5 | 6 | 40 / 50 | 10 / 20 | 375-650 | 800 x 900 | MSEP |

2.c | ENVIROX – 800 SDB | 800 | 2500 | 5 | 6 | 40 / 50 | 10 / 20 | 650-900 | 1000 x 900 | MSEP |

3.a | ENVIROX – 1000 SD | 1000 | 2000 | 5 | 6 | 50 / 80 | 15 / 30 | 600-1000 | 1000 x 900 | MSEP |

3.b | ENVIROX – 1000 SDB | 1000 | 2500 | 5 | 6 | 50 / 80 | 15 / 30 | 1000-1400 | 1200 x 900 | MSEP |

4.a | ENVIROX – 1200 SD | 1200 | 2000 | 5 | 6 | 65 / 80 | 22 / 50 | 850-1400 | 1200 x 900 | MSEP |

4.b | ENVIROX – 1200 SDB | 1200 | 2500 | 5 | 6 | 65 / 80 | 22 / 50 | 1400-2000 | 1400 x 900 | MSEP |

5.a | ENVIROX – 1400 SD | 1400 | 2000 | 5 | 6 | 80 / 100 | 30 / 60 | 1150-2000 | 1400 x 900 | MSEP |

5.b | ENVIROX – 1400 SDB | 1400 | 2500 | 5 | 6 | 80 / 100 | 30 / 60 | 1900-2750 | 1600 x 900 | MSEP |

6.a | ENVIROX – 1600 SD | 1600 | 2000 | 6 | 8 | 80 / 100 | 40 / 80 | 1500-2500 | 1600 x 900 | MSEP |

6.b | ENVIROX – 1600 SDB | 1600 | 2500 | 6 | 8 | 80 / 100 | 40 / 80 | 2500-3600 | 1800 x 900 | MSEP |

7.a | ENVIROX – 1800 SD | 1800 | 2000 | 6 | 8 | 80 / 100 | 50 /100 | 1900-3200 | 1800 x 900 | MSEP |

7.b | ENVIROX – 1800 SDB | 1800 | 2500 | 6 | 8 | 100 / 150 | 50/100 | 3200-4500 | 2200 x 900 | MSEP |

8.a | ENVIROX – 2000 SD | 2000 | 2000 | 6 | 8 | 100 / 150 | 60/ 120 | 2400-4000 | 2000 x 900 | MSEP |

8.b | ENVIROX – 2000 SDB | 2000 | 2500 | 6 | 8 | 100 / 150 | 60/ 120 | 4000-5600 | 2400 x 900 | MSEP |

9.a | ENVIROX – 2200 SD | 2200 | 2000 | 8 | 10 | 100 / 150 | 75/150 | 3000-4800 | 2200 x 900 | MSEP |

9.b | ENVIROX – 2200 SDB | 2200 | 2500 | 8 | 10 | 100 / 150 | 75 / 150 | 4800-6800 | 2600 x 900 | MSEP |

10.a | ENVIROX – 2400 SD | 2400 | 2000 | 8 | 10 | 100 / 150 | 90/180 | 3400-5700 | 2400 x 900 | MSEP |

10.b | ENVIROX – 2400 SDB | 2400 | 2500 | 8 | 10 | 100 / 150 | 90/180 | 5700-8000 | 2800 x 900 | MSEP |

If you have any questions let us know

Do you have any questions? Write and our specialists will answer you.