- Home

- Water Filtration Plants

Water Filtration Plants

Water Filtration Plants

- PSF: These filters are filled with gravels & fine quartz silica and designed on low filtration rate vary between 10 to 12.5 m3/hr/m2 for water treatment and 24m3/hr/m2 for swimming pool filtration. These filters are designed with a low HOS of 1200 mm.

- DMF: These filters are filled with dual media consist of coarse & fine quartz silica followed by anthracite and designed for filtration rate vary between 12.5 – 15 m3/hr/m2. for sewage & effluent water filtration and 15 – 18 m3/hr/m2 for water treatment. These filters are designed for HOS up to 1.8 m.

- MGF: These filters are filled with multi media consist of coarse & fine quartz silica followed by anthracite, Mno2 or granular activated carbon and designed at high filtration rate vary from 15- 24 m3hrm2. These filters are designed for HOS vary between 1.875 – 2.5 m.

- IRF : These filters are designed using special iron removal media like MnO2 or Manganese Greensand or Purolite MZ10 Plus with bed depth depending on Iron Contents in raw water. The IRF Media layer is supported by gravels & coarse media in iron removal filters. Based on design Iron can be reduced upto 20 ppm.

- ACF : after juices using very high quality coconut shell based granular activated carbon media having Iodized value not less than 1100mg. The other usage for activated carbon filters are in waste water treatment where organics removal become essential before disposal of treated waste water. Our activated carbon filters are designed at filtration rate vary from 9-15 m3/hr/m2 and capable to treat sewage or efficient water after biological treatment.

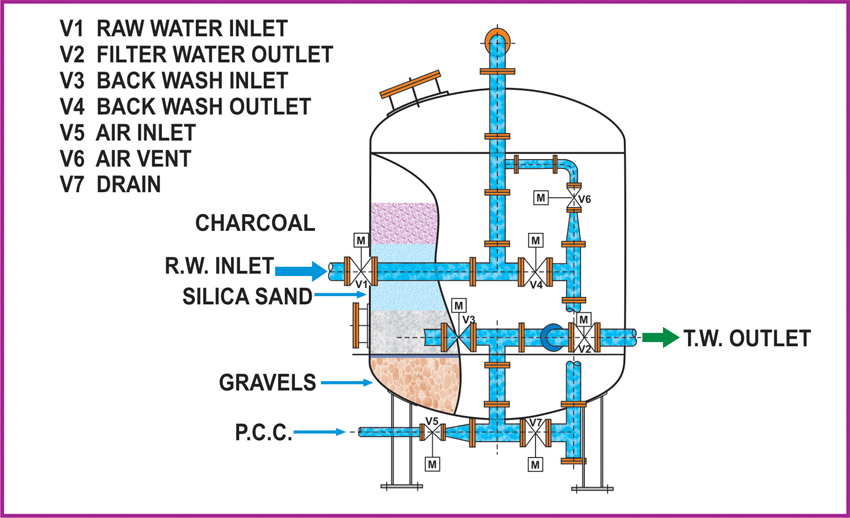

UNDER DRAIN SYSTEM

Each filter will be provided with an efficient under drain system comprising of collecting pipes, polyproplene nozzle’s as per design & engineering. The entire under drain system will be supported on M.S. Bed Plate or cement concrete supports based on filter vessel diameter. In some cases, header pipes with laterals covered with big size pebbles, to prevent loss of fine Silica Sand are provided

FILTER MEDIA

The under bed material for the filter consists of two layer of gravels, one layer of coarse, one layer of fine sand and one layer of anthracite (if required) media. In bigger size filters where pipe header with laterals are provided extra big size pebbles are also filled to cover header pipe of collecting system.

FRONTAL PIPE WORK & VALVES

All filters are provided with interconnecting face piping in M.S. comprising of inlet, outlet and back wash lines complete with valves for individual operations. The waste effluents are directed to a drain sump for which a pipe to drain should be connected.

ACCESSORIES

- Air release valve with connecting piping.

- 100 mm dia Dial Bourden type gun metal pressure gauges with gun metal isolation, cock and connecting piping on inlet and outlet, causing shall be with cast aluminium stored enamel black finish cases.

- Sampling cocks on water inlet and filtered water outlet.

- Connection with valve for air scouring, in case Air Blower is provided for AIR SCOURING of filter.

Available in different sizes and capacity ranges from 5 cum. to 160 cum. per hour rate of flow. For best designing of suitable filter, kindly provide complete detail as per below on our E-Mail : vkenvirotech@gmail.com :

- Flow rate through filter

- Feed water quality ( Turbidity & Suspended solids )

- Application of treated water

TECHNICAL DATA OF MULTIGRADE FILTERS | ||||||||||

Sr. Nos. | Model | Diameter (mm) | H.O.S. (mm) | Thickness (mm) | Frontal Piping (mm) | Max. Flow Rate m3/hr.* | Media Volume | Media Depth in (mm) | Remarks | |

Shell | Dish End | |||||||||

1. | ENVIROX – 600 MGF | 600 | 2300 | 5 | 5 | 50 | 6.5 | 0.27 cum. | 950 | MSEP |

2. | ENVIROX – 800 MGF | 800 | 2300 | 5 | 5 | 50 | 11.0 | 0.48 cum. | 950 | MSEP |

3. | ENVIROX – 1000 MGF | 1000 | 2300 | 5 | 5 | 80 | 17.3 | 0.75 cum. | 950 | MSEP |

4. | ENVIROX – 1200 MGF | 1200 | 2300 | 5 | 6 | 80 | 25.0 | 1.10 cum. | 950 | MSEP |

5. | ENVIROX – 1400 MGF | 1400 | 2300 | 5 | 6 | 100 | 34.0 | 1.46 cum. | 950 | MSEP |

6. | ENVIROX – 1600 MGF | 1600 | 2300 | 6 | 8 | 100 | 44.0 | 1.90 cum. | 950 | MSEP |

7. | ENVIROX – 1800 MGF | 1800 | 2300 | 6 | 8 | 100 | 56.0 | 2.41 cum. | 950 | MSEP |

8. | ENVIROX – 2000 MGF | 2000 | 2300 | 6 | 8 | 150 | 69.0 | 3.00 cum. | 950 | MSEP |

9. | ENVIROX – 2200 MGF | 2200 | 2000 | 8 | 10 | 150 | 84.0 | 3.60 cum. | 950 | MSEP |

10. | ENVIROX – 2400 MGF | 2400 | 2000 | 8 | 10 | 150 | 99.0 | 4.30 cum. | 950 | MSEP |

11. | ENVIROX – 2600 MGF | 2600 | 2000 | 10 | 12 | 150 | 116.0 | 5.00 cum. | 950 | MSEP |

12. | ENVIROX – 2800 MGF | 2800 | 2000 | 10 | 12 | 200 | 135.0 | 5.85 cum. | 950 | MSEP |

13. | ENVIROX – 3000 MGF | 3000 | 2000 | 10 | 12 | 200 | 155.0 | 6.71 cum. | 950 | MSEP |

14. | ENVIROX – 3200 MGF | 3000 | 2000 | 10 | 12 | 200 | 175.0 | 7.63 cum. | 950 | MSEP |

- The flow rate given is designed on inlet suspended solids as 25 mg./l.